Hanlinrui is a professional China aluminum alloy piston manufacturer and supplier. Hanlinrui continuously reduces costs through technological innovation and process optimization. From raw material procurement to production processing, logistics and distribution, and other various aspects, Hanlinrui strives for excellence. This not only provides customers with a more competitive price advantage but also enhances our overall external competitiveness.

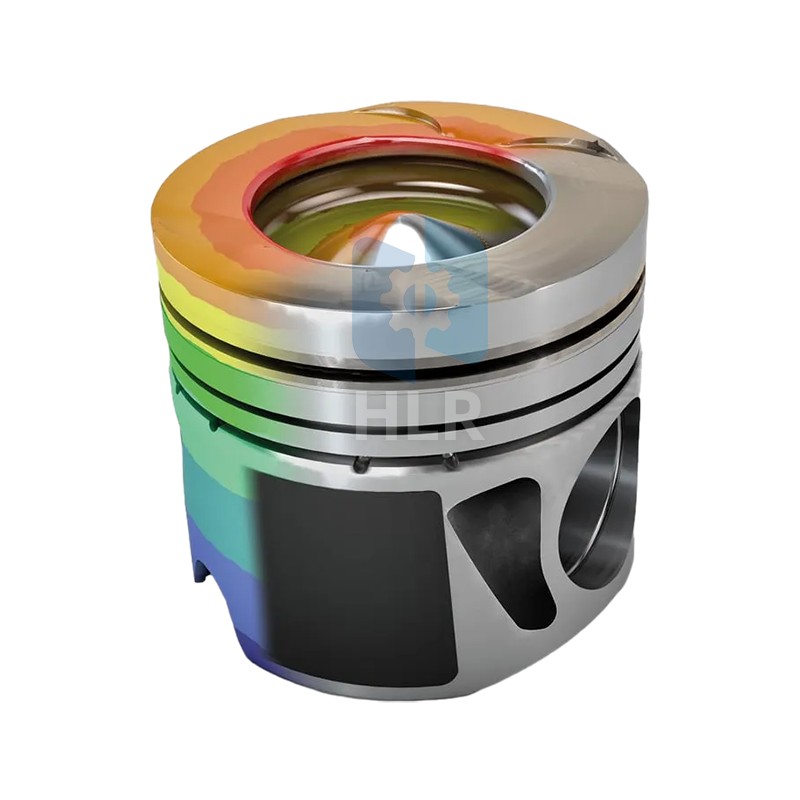

Aluminum alloy piston is a key component widely used in internal combustion engines, compressors, and other mechanical equipment. Made from high-quality aluminum alloy materials, aluminum alloy piston boasts characteristics such as light weight, good thermal conductivity, strong wear resistance, and high mechanical strength.

|

Specification Parameter |

Common Range/Example Value/Description |

|

Piston Diameter (mm) |

Various sizes available, such as 60, 62, 70, etc. |

|

Piston Height (mm) |

Various sizes available, such as 45, 49, 50, etc. |

|

Pin Hole Diameter (mm) |

Customized according to engine requirements, e.g., 14.5, etc. |

|

Material |

Aluminum alloy (different alloy types such as aluminum-silicon alloy, aluminum-copper alloy, etc., can be selected based on specific needs) |

|

Surface Treatment |

Anodizing, painting, electroplating, etc. (color, gloss, and other features can be customized based on requirements) |

|

Weight (g) |

Customized according to specific dimensions and material |

● Structural Optimization: The design of aluminum alloy pistons often involves the use of finite element analysis (FEA) and other techniques to optimize the structure, ensuring the piston has the best distribution of strength and stiffness when subjected to combustion pressures.

● Cooling Channel Design: The top and sides of the piston may be designed with intricate cooling channels that help dissipate heat more effectively, reduce thermal stress, and enhance the durability of the piston.

● Wear-Resistant Coatings: To reduce wear, the piston skirt may be coated with special wear-resistant materials such as ceramic or diamond coatings, which provide additional protection and extend the lifespan of the piston.

● Oil Film Retention Grooves: The design of oil film retention grooves in the piston skirt helps maintain oil film stability during high-speed operation, reducing friction and wear, and improving the piston's performance.

● Lightweight Honeycomb Structure: By incorporating lightweight honeycomb structures in non-critical areas of the piston, it is possible to further reduce the weight of the piston, which enhances the engine's responsiveness and fuel efficiency.

|

High-quality raw materials |

Our products use high-quality raw materials that have been carefully screened to ensure the quality and safety of the final product. |

|

Advanced technology |

The latest processing technology and equipment are used to ensure the finishing level and consistency of the products. |

|

Quality Control |

Implement a strict quality control process to ensure that every product meets high standards. |

|

Customized service |

Provide customized service to adjust product specifications and formulas according to customer needs. |

|

Innovative R&D |

Continue to invest in R&D and continuously launch innovative products to meet new market needs. |

● Lightweight: Compared to cast iron and steel pistons, aluminum alloy pistons are significantly lighter. This reduction in weight helps to decrease the overall weight of the engine, leading to improved engine power and fuel efficiency.

● Excellent Thermal Conductivity: Aluminum alloy pistons exhibit good thermal conductivity, allowing them to quickly disperse the high temperatures and heat generated by fuel combustion. This effectively lowers the engine's temperature and reduces thermal losses.

● Low Coefficient of Thermal Expansion: Aluminum alloy pistons have a relatively low coefficient of thermal expansion, ensuring stable operation under extreme conditions and reducing the probability of failure.

● Corrosion Resistance: Although aluminum alloy pistons may not have the highest corrosion resistance compared to some other materials, they are still capable of tolerating certain chemical substances, providing a degree of protection against corrosion.

● Durability and Wear Resistance: By optimizing the alloy composition, such as adding appropriate elements like tin (Sn), lead (Pb), zinc (Zn), chromium (Cr), and titanium (Ti), aluminum alloy pistons can be made more durable and wear-resistant.

Q: Is it suitable for my engine?

A: It depends on your engine model to determine compatibility.

Q: Are aluminum alloy pistons durable?

A: They are very durable, but their lifespan depends on usage and maintenance.

Q: Can aluminum alloy pistons be used in both gasoline and diesel engines?

A: Yes, but the design and material may vary.

Q: Do aluminum alloy pistons require special maintenance?

A: No, regular maintenance is sufficient.

Q: Can it replace a cast iron piston?

A: Yes, but ensure compatibility.