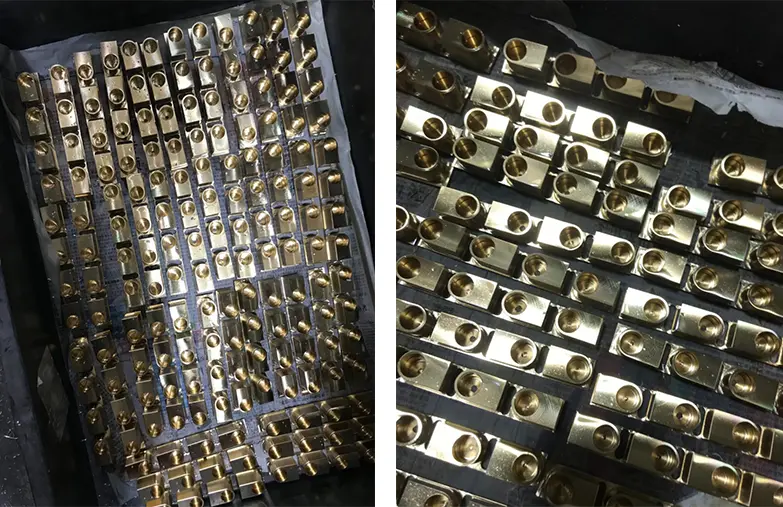

Qingdao Hanlinrui Machinery Co., Ltd. is a company specialising in the metal products industry, with a particular focus on CNC bronze machining. Utilising state-of-the-art CNC machine tools, HANLINRUI produces CNC bronze machined parts that are renowned for their high strength, good abrasion and corrosion resistance, making them ideal for use in a variety of complex and precise machinery. The company's high-quality CNC bronze machining has won wide recognition and trust from customers at home and abroad.

Qingdao Hanlinrui Machinery Co., Ltd. offers advanced CNC bronze machining that combines the excellent properties of bronze material with the precision of CNC machining technology. Bronze, an alloy of tin, copper and phosphorus, has good hardness, strength and wear resistance, making it ideal for use in the manufacture of wear-resistant parts in precision instruments, such as bearings, gears and bushings. Additionally, CNC Bronze Machining's products exhibit exceptional resistance to corrosion in seawater, rendering them highly suitable for marine applications, such as the fabrication of components for pumps and pipe fittings.

CNC Bronze Machining, conversely, has been demonstrated to achieve efficient and accurate machining of bronze materials through the utilisation of precise programming and control.During CNC machining, the bronze material is cut, ground and subjected to other processes to be machined into components that meet the design requirements. This method of machining has been shown to enhance production efficiency, reduce human error and ensure the quality and accuracy of the components.

The scope of CNC Bronze Machining is extensive, with applications ranging from the aerospace industry, where it is employed in the manufacture of critical components for aircraft engines, to the automotive sector, where bronze bearings, gears, and other components contribute to enhanced performance and reliability of automobiles. The chemical industry, marine engineering, and numerous other fields also stand to benefit from the utilisation of bronze components.

In summary, CNC bronze machining is an efficient, precise and environmentally friendly manufacturing process with a wide range of application prospects in various fields. Technological progress and market expansion will continue to open up new development space and opportunities for CNC bronze machining.

|

OEM SERVICE |

||

|

Cnc Milling |

Cnc Turning |

Cnc Machining |

|

Laser Cutting |

Cnc Prototype |

Jig/Fixture |

|

Other metal fabrication,like Stamping,Bending,Casting.etc. |

||

|

Available Drawings Format |

stp, step, igs, iges, x_t, sat,sldxml, prt,dxf, dwg, PDF, jpg, jpeg, png, etc. |

|

Raw Material |

Bronze:H62,H65.H90,HA177-2,HPb59-1, HSn70-1 etc. |

|

Manufacturing Service |

CNC machining,milling,turning,grinding, wire EDM cutting,cnc prototype/jig/fixture,laser cutting,other metal fabrication,like Stamping,Bending,Casting.etc. |

|

Tolerance |

Highest = +/-0.005mm or +/- 0.0002 inch |

|

Surface Roughness |

Ra0.4 (milled or turned without polishing or grinding) |

|

Finish |

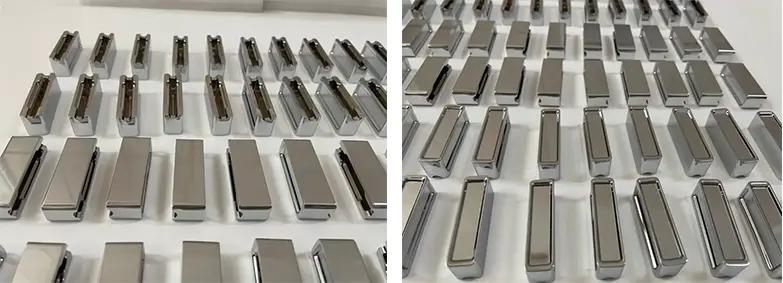

Polishing,mirror polishing,brushing, sandblasting, heat treatment etc. |

|

Surface Treatment |

Anodizing,blackening,electroplating(zinc,nickel,chrome),electrophoresis, painting,powder coating,passivate,carburize etc. |

|

Logo |

Laser engraving, CNC engraving, screen-printing etc. |

High precision and quality:

CNC bronze machining enables high-precision machining of bronze materials through precise programming and control, ensuring dimensional, shape and positional accuracy of parts. High-quality machined surfaces and edges reduce the need for subsequent processing and improve the overall quality of the product.

Efficient production:

CNC bronze machining enables continuous and stable machining, which greatly improves productivity and reduces cycle times and costs.

Flexibility and Versatility:

CNC bronze machining is capable of machining bronze parts of various complex shapes and structures to meet diverse design requirements.

High material utilisation:

CNC bronze machining can accurately control the amount of material to be removed, reducing waste and improving material utilisation. It is suitable for small-lot and customised production, reducing production costs.

Good machinability:

Bronze material has good ductility and plasticity, suitable for CNC machining.

CNC bronze machining process is not easy to produce cracks and deformation, which ensures the stability and reliability of the parts.

Environmentally friendly and sustainable:

CNC bronze machining produces less waste and is easy to recycle and reuse. By optimising machining parameters and adopting more environmentally friendly machining methods, energy consumption and emissions can be further reduced to achieve green production.