Sand casting is a well-established and widely used casting method that employs moulding materials, such as casting sand and sand binder, to produce a casting of a specified shape. The casting is then injected with molten metal or alloy liquid by gravity or other external forces, and subsequently removed after cooling and solidification. This casting method is suitable for the production of a variety of metals and alloys, including steel, iron and most non-ferrous alloy castings.

Sand casting is a highly popular method due to the low cost and ease of access to modelling materials, as well as the simplicity and adaptability of the casting manufacturing process. Sand casting is suitable for a wide range of production volumes, from single pieces to batches and mass production. Furthermore, sand casting is typically employed in an outer sand and core configuration. The sand exhibits a certain degree of permeability and concessions, making it particularly well-suited for the production of highly complex shapes and cavity blanks.

The fundamental materials used in the production of sand moulds are casting sand and sand binder. The most commonly used casting sand is siliceous sand, while specialty sands such as zircon sand, chromite sand and corundum sand are used in special cases, for example, when the high-temperature properties of siliceous sand do not meet the required specifications. The purpose of the sand binder is to bond the loose sand particles together to form a sand pattern with a certain strength.

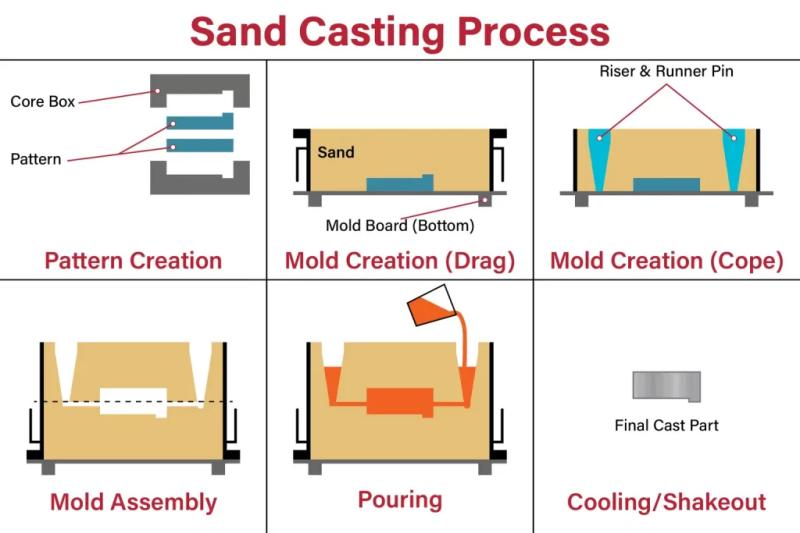

The sand casting process comprises the following steps: sand preparation, mould making, core making, melting, pouring, cleaning, processing and inspection. The sand preparation stage requires the preparation of sand and core sand, while the mould-making stage involves the production of moulds and core boxes in accordance with the specifications set out in the part drawings. Once the melting stage has produced a suitable liquid metal, the next step is to pour it. Once the molten metal has solidified, it is cleaned and processed before being inspected to ensure the quality of the castings.

Sand casting plays an important role in the foundry industry, offering unique advantages and a wide range of applications.